Are you considering purchasing a CNC mill machine? Whether you're a seasoned machinist or just starting out in the world of machining, buying a CNC mill machine can be a significant investment. It's crucial to make an informed decision to ensure you get the right machine for your needs and budget.

In this comprehensive guide, we will walk you through the process of purchasing a CNC mill machine. We'll start by covering the basics of CNC mill machines, including how they work and their various applications. This will give you a solid understanding of what to look for when evaluating potential machines.

Next, we'll discuss the pros and cons of buying new versus used CNC mill machines. Weighing the benefits and drawbacks of each option will help you make an informed decision based on your specific requirements and budget.

If you're considering buying a used machine, we'll provide valuable insights on what to look for during the inspection process. Our detailed inspection checklist will ensure you don't overlook any critical components or potential issues.

Finding CNC mill machines for sale can be a challenge, but we've got you covered. We'll explore various avenues, including online marketplaces, manufacturer websites, and local dealers and auctions. You'll learn where to find the best deals and how to navigate the purchasing process with confidence.

Once you've found the perfect machine, we'll guide you through the final steps of the purchase. You'll discover tips on negotiating the price, organizing delivery, and setting up your new CNC mill machine. Our goal is to make the entire process as smooth and hassle-free as possible.

Whether you're a hobbyist looking to upgrade your workshop or a business owner seeking to expand your capabilities, this guide will equip you with the knowledge and tools to make an informed decision when purchasing a CNC mill machine. So let's dive in and unlock the world of CNC machining with confidence!

Understanding CNC Mill Machine Basics

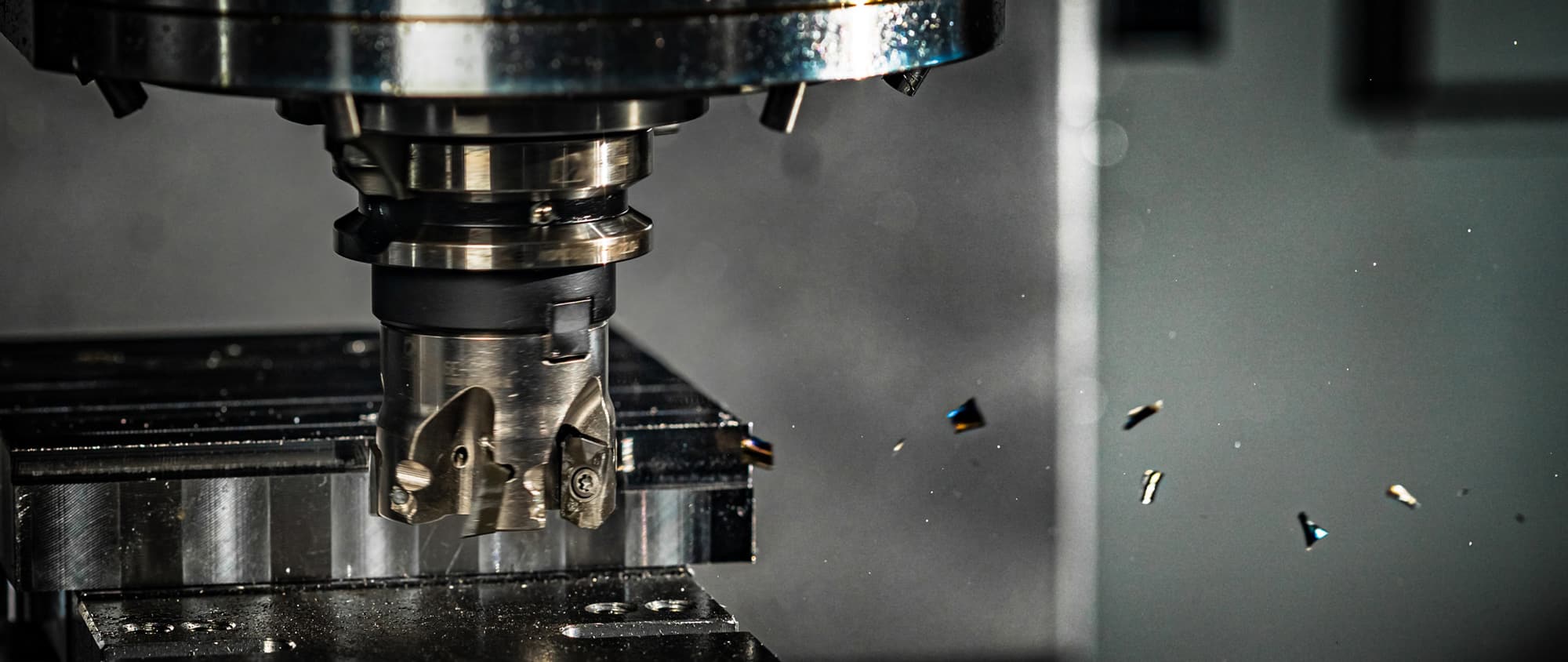

A CNC mill machine, also known as a computer numerical control mill machine, is a powerful tool used in the manufacturing industry. It utilizes computerized controls to automate the milling process, resulting in precise and efficient machining operations.

In this section, we will delve into the basics of CNC mill machines to provide you with a solid foundation of knowledge. Understanding how these machines work and their various components will help you make informed decisions when purchasing one.

How Does a CNC Mill Machine Work?

At its core, a CNC mill machine is designed to remove material from a workpiece using rotary cutters. The machine's computerized controls dictate the movement of the cutting tools, allowing for precise and accurate cuts.

The CNC mill machine operates on a Cartesian coordinate system, where the workpiece is positioned along the X, Y, and Z axes. The machine's software translates the design specifications into machine-readable code, typically using G-code programming language. This code instructs the machine on tool paths, spindle speed, and feed rate.

The machine's cutting tools, such as end mills or drills, are mounted on a spindle that rotates at high speeds. The cutting tools move along the designated paths, making precise cuts and shaping the workpiece according to the programmed specifications.

Components of a CNC Mill Machine

To understand the inner workings of a CNC mill machine, it's essential to familiarize yourself with its key components. Here are the main components you should be aware of:

- Control Panel: This is where the operator interacts with the machine, inputting commands and monitoring the machining process.

- Spindle: The spindle holds the cutting tools and rotates them at high speeds. It plays a crucial role in determining the machine's cutting capabilities.

- Worktable: The worktable is the surface on which the workpiece is secured during machining. It can move along the X and Y axes to position the workpiece accurately.

- Guideways: Guideways provide support and guidance for the movement of the machine's components. They ensure smooth and precise motion along the axes.

- Tool Changer: Some CNC mill machines are equipped with automatic tool changers, allowing for quick and efficient tool swaps during machining operations.

- Coolant System: CNC mill machines often feature a coolant system to lubricate and cool the cutting tools, preventing overheating and prolonging tool life.

Understanding these components and their functions will help you evaluate the quality and capabilities of different CNC mill machines.

Applications of CNC Mill Machines

CNC mill machines find applications in various industries, including:

- Aerospace: CNC mill machines are used to produce complex components for aircraft and spacecraft, such as engine parts and structural components.

- Automotive: These machines are utilized in the automotive industry to manufacture precision parts, including engine blocks, transmission components, and chassis parts.

- Medical: CNC mill machines are employed in the production of medical devices and implants, ensuring high precision and quality in the manufacturing process.

- Prototyping: Rapid prototyping is made possible with CNC mill machines, allowing designers to quickly create and iterate on product prototypes.

- Custom Fabrication: CNC mill machines are used by custom fabrication shops to create unique and intricate metalwork, architectural elements, and artistic pieces.

Understanding the diverse applications of CNC mill machines will help you determine the specific features and capabilities you need based on your intended use.

By grasping the fundamentals of CNC mill machines, including their working principles, key components, and applications, you'll be well-equipped to navigate the purchasing process with confidence. In the next section, we'll explore the pros and cons of buying new versus used CNC mill machines, providing you with valuable insights to make an informed decision.

New vs Used CNC Mill Machines

When it comes to purchasing a CNC mill machine, one of the key decisions you'll need to make is whether to buy a new or used machine. Both options have their advantages and considerations, and in this section, we will explore the pros and cons of each to help you make an informed choice.

Pros of Buying New CNC Mill Machines

- Reliability and Warranty: New machines typically come with warranties, providing peace of mind and protection against any potential issues. You can rely on the manufacturer's support and assistance in case of technical problems.

- Latest Technology: New CNC mill machines often incorporate the latest technological advancements, offering improved performance, precision, and efficiency. You'll have access to cutting-edge features and software capabilities.

- Customization Options: Purchasing a new machine allows you to customize various aspects, such as the size, power, and additional features, to meet your specific requirements. This ensures that the machine aligns perfectly with your intended applications.

- Minimal Maintenance: New machines generally require less maintenance early on, as they haven't accumulated wear and tear. This can save you time and money in the initial stages of machine ownership.

- Training and Support: Manufacturers of new machines often provide training programs and support to help you get started with your new CNC mill machine. This can be valuable, especially if you're new to CNC machining.

Cons of Buying New CNC Mill Machines

- Higher Cost: Buying a new CNC mill machine can be significantly more expensive compared to purchasing a used one. The latest technology and warranty coverage often come at a premium price.

- Depreciation: Similar to other high-value machinery, new CNC mill machines can experience depreciation in value over time. As soon as you purchase a new machine, its value may decrease.

- Limited Availability: Depending on your specific requirements, finding the exact new CNC mill machine you need may take time. Availability can be limited, especially for specialized or niche machines.

Pros of Buying Used CNC Mill Machines

- Cost Savings: One of the most significant advantages of buying a used CNC mill machine is the potential for substantial cost savings. Used machines are typically priced lower than new ones, allowing you to stretch your budget further.

- Immediate Availability: Used machines are readily available on the market, offering a wide selection to choose from. You can find machines with specific features and capabilities that may no longer be offered in new models.

- Value Retention: While new machines experience initial depreciation, used CNC mill machines tend to retain their value more steadily. This can be beneficial if you plan to resell the machine in the future.

Cons of Buying Used CNC Mill Machines

- Uncertain Condition: Used machines come with a level of uncertainty regarding their condition. There is a risk of hidden issues or wear and tear that may require costly repairs or replacement parts.

- Limited Warranty or Support: Unlike new machines, used machines may not come with a warranty or manufacturer support. You'll need to rely on your own knowledge or the expertise of a trusted technician.

- Outdated Technology: Used machines may not incorporate the latest technological advancements or software updates. This can limit your capabilities and potential for efficiency gains.

Carefully weighing these pros and cons will help you determine whether a new or used CNC mill machine is the right choice for your specific needs and budget. In the next section, we will delve further into the considerations and factors to look for when buying a used CNC mill machine.

Where to Find CNC Mill Machines for Sale

When you're ready to purchase a CNC mill machine, you'll need to know where to find reliable sellers and reputable sources. In this section, we'll explore various avenues where you can find CNC mill machines for sale, ensuring you have access to a wide range of options to choose from.

Online Marketplaces

- eBay: eBay is a popular online marketplace where you can find both new and used CNC mill machines. It offers a diverse selection from different sellers, allowing you to compare prices and specifications.

- Amazon: While primarily known for consumer goods, Amazon also has a section dedicated to industrial machinery, including CNC mill machines. You can browse through various options and read customer reviews to make an informed choice.

- Alibaba: Alibaba is a global online marketplace that connects buyers and sellers from around the world. It offers a vast selection of CNC mill machines, including both new and used options. However, be sure to verify the credibility of the sellers before making a purchase.

- Machinery Auctions: Online auction platforms like Machinery Auctioneers and Bidspotter regularly feature CNC mill machines up for bidding. Participating in these auctions can often lead to great deals, but be prepared to compete with other buyers.

Manufacturer Websites

- Haas Automation: Haas Automation is a well-known manufacturer of CNC mill machines. Their website provides comprehensive information about their product lineup and allows you to request a quote directly from the manufacturer.

- DMG Mori: DMG Mori is another reputable manufacturer that offers a range of CNC mill machines. Their website provides detailed specifications and features for each machine, along with the option to request a quote or get in touch with a representative.

- FANUC: FANUC is a leading manufacturer of CNC systems and machinery. While they primarily specialize in CNC controls, their website includes a directory of authorized FANUC CNC machine tool dealers. You can connect with these dealers to explore available CNC mill machines.

Local Dealers and Auctions

- Industrial Machinery Dealers: Local machinery dealers specializing in industrial equipment often have CNC mill machines for sale. These dealers can provide personalized assistance, allowing you to inspect the machines in person and ask any questions you may have.

- Equipment Auctions: Keep an eye out for local equipment auctions, as they often feature CNC mill machines among other industrial machinery. These auctions can be a great opportunity to find used machines at competitive prices.

- Trade Shows and Expos: Attending trade shows and expos related to the manufacturing industry can give you the chance to see various CNC mill machines in action. Manufacturers and dealers often showcase their machines at these events, allowing you to connect with them directly.

By exploring these avenues, you'll have access to a wide range of CNC mill machines for sale. Take the time to compare prices, specifications, and seller reputations to ensure you find the right machine that meets your specific needs. In the next section, we'll discuss how to evaluate a CNC mill machine before making a purchase to ensure you're getting a reliable and high-quality machine.

How to Evaluate a CNC Mill Machine Before Purchase

Evaluating a CNC mill machine thoroughly before making a purchase is crucial to ensure you're investing in a reliable and high-quality machine. In this section, we will provide you with a comprehensive evaluation checklist and guide to help you assess the condition, specifications, and performance of a CNC mill machine.

Inspection Checklist

- Physical Condition: Inspect the machine for any signs of physical damage, such as dents, rust, or worn-out components. Pay attention to the overall cleanliness and maintenance of the machine.

- Guideways and Slideways: Check the guideways and slideways for signs of wear or damage. These components play a vital role in the machine's accuracy and smooth movement.

- Spindle: Evaluate the condition of the spindle, including its runout and overall performance. Excessive runout or noise can indicate potential issues.

- Electrical Components: Check the electrical components, such as wiring, connectors, and control panels, for any signs of damage or malfunction. Ensure all buttons, switches, and indicators are in working condition.

- Coolant System: Inspect the coolant system, including the tank, pumps, and nozzles. Ensure the system is clean and functional, as a properly functioning coolant system is crucial for efficient machining.

- Tool Changer (if applicable): If the machine has an automatic tool changer, test its functionality and ensure smooth tool changes without any errors or issues.

- Controller and Software: Evaluate the machine's controller and software. Check if they are up to date and compatible with the desired operations. Ensure the software is user-friendly and intuitive.

Understanding Specifications

- Work Area: Determine the size of the machine's work area, including the maximum X, Y, and Z axis travel. Ensure that the work area is sufficient for your intended applications.

- Spindle Speed and Power: Consider the spindle speed range and power. Higher spindle speeds allow for faster machining, while higher power enables the machine to handle more demanding materials and cutting operations.

- Tool Capacity: If the machine has a tool changer, determine the number of tools it can accommodate. Consider the tool capacity based on your specific machining needs.

- Accuracy and Repeatability: Look for specifications related to accuracy and repeatability, such as positioning accuracy and repeatability. These specifications indicate the machine's ability to achieve precise and consistent results.

Testing the Machine

- Run a Test Program: Ask the seller if you can run a test program on the machine to evaluate its performance. This will help you assess its accuracy, smoothness of operation, and overall functionality.

- Test Different Tool Paths: Perform test cuts using various tool paths and materials to evaluate the machine's cutting capabilities. Pay attention to the quality of the surface finish, precision, and overall performance.

- Check for Excessive Vibration or Noise: During operation, listen for any unusual noises or excessive vibrations. Excessive vibration or noise can indicate mechanical issues or poor machine condition.

By following this evaluation checklist and conducting thorough tests, you can ensure that the CNC mill machine you're considering is in good condition and meets your specific requirements. Taking the time to evaluate the machine before purchase can save you from potential problems and ensure that you're making a wise investment. In the next section, we'll guide you through the final steps of the purchasing process, including negotiating the price, organizing delivery, and setting up your new CNC mill machine.

Finalizing the Purchase: Payment, Delivery, and Setup

Once you have selected the CNC mill machine that meets your requirements and completed the evaluation process, it's time to finalize the purchase. In this final section, we will guide you through the essential steps of negotiating the price, organizing delivery, and setting up your new CNC mill machine.

Negotiating the Price

- Research Comparable Machines: Before entering into price negotiations, research the market value of similar CNC mill machines. This will give you a benchmark to determine a fair price and provide leverage during negotiations.

- Highlight any Issues or Maintenance Requirements: If you identified any issues or maintenance requirements during the evaluation, use them as leverage to negotiate a lower price. Factor in the cost of repairs or replacements when discussing the price.

- Consider Additional Costs: Keep in mind any additional costs associated with the purchase, such as transportation, installation, or any necessary upgrades. Account for these costs when negotiating the final price.

- Be Willing to Walk Away: Don't be afraid to walk away if the seller is not willing to negotiate a fair price. There are often other options available, and it's better to find a machine that fits within your budget and meets your expectations.

Organizing Delivery

- Choose a Trusted Delivery Service: If the seller does not provide delivery services, research and select a reliable and reputable delivery service that specializes in handling heavy machinery. Ensure they have experience transporting CNC mill machines safely.

- Discuss Insurance Coverage: Confirm whether the delivery service provides insurance coverage for any potential damages or losses during transportation. It's crucial to have adequate protection during the delivery process.

- Coordinate Logistics: Work closely with the delivery service to determine the logistics of the delivery, including pickup and drop-off locations, timing, and any special requirements for unloading the machine.

Setting Up Your New CNC Mill Machine

- Prepare the Workspace: Clear and prepare the designated workspace for your CNC mill machine. Ensure you have sufficient space, proper ventilation, and access to necessary power sources.

- Secure Necessary Permits and Clearances: Check if any permits or clearances are required for setting up a CNC mill machine in your area. Compliance with local regulations will ensure a smooth installation process.

- Follow Manufacturer's Instructions: Read and follow the manufacturer's instructions for setting up the CNC mill machine. This may involve leveling the machine, connecting power and coolant lines, and calibrating the machine.

- Perform Initial Test Runs: Once the machine is set up, perform initial test runs to ensure it is functioning properly. Verify the accuracy, smoothness of operation, and the performance of the machine.

By carefully considering the price, organizing reliable delivery, and following proper setup procedures, you can ensure a smooth and successful transition to owning and operating your new CNC mill machine. Congratulations on your purchase, and may your new machine bring you many productive and successful machining operations!